Tank Process Vats

Tank Process Vats Specification

- Heating Method

- Steam / Electric / No Heating (optional)

- Features

- Seamless Finish, Rugged Construction, High Durability

- Noise Level

- Low

- Automation Grade

- Semi-Automatic / Automatic

- Speed Mode

- Fixed/Variable (with Optional Agitator)

- Phase

- Single/Three Phase

- Feeding System

- Top Lid/Open Manhole

- Frequency

- 50 Hz

- Power Source

- Electric

- Operating Temperature

- Up to 120C

- Machine Type

- Industrial Process Vessel

- Function Type

- Mixing / Holding / Processing

- Product Type

- Tank / Vat

- General Use

- Mixing, Storage, Fermentation - Dairy, Food, Chemical, Pharma

- Material

- Stainless Steel

- Type

- Process Vat

- Capacity

- 200 Litre to 10000 Litre (Custom Size Available)

- Weight (kg)

- Variable (depends on size)

- Product Shape

- Cylindrical

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual / PLC Based (optional)

- Installation Type

- Floor Mounted

- Voltage

- 220-415 V

- Power

- Customizable as per capacity

- Dimension (L*W*H)

- Custom Fabricated (as per requirement)

- Raw Material

- Stainless Steel SS304/SS316

- Feature

- Leak Proof, Corrosion Resistant, Easy Cleaning

- Color

- Metallic Silver

- Gasket Material

- Food Grade Silicone / EPDM

- Test Pressure

- As per design (0.5 to 3 bar standard)

- Surface Finish

- Mirror / Matt Finish

- Accessories

- Level Indicator, Temperature Gauge, CIP Nozzle

- Mobility

- Fixed / Portable (with Wheels)

- Outlet Valve

- SS Ball Valve / Butterfly Valve

- Agitator Type

- Available with Anchor, Paddle, or Custom (as required)

- Insulation

- Optional PUF/Glass Wool

- Usage

- Dairy, Beverage, Food Processing, Pharmaceutical, Chemical

- Design Standard

- cGMP / ASME / BIS as applicable

- Top Cover Type

- Clamp-on / Hinged / Openable

Tank Process Vats Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Tank Process Vats

Versatile Agitator & Customizable Design

Our process vats come with a choice of agitators Anchor, Paddle, or customized as per process needs. The fully configurable design allows selection of insulation, surface finish, accessories, and outlet valves, ensuring each unit is tailored to your applications demands. We fabricate to custom dimensions, so each tank integrates seamlessly into your operation.

Superior Hygiene & Quality Compliance

Manufactured from high-grade SS304/SS316 stainless steel and available with mirror or matt finishes, these tanks meet stringent cGMP, ASME, and BIS standards. Features like food-grade silicone/EPDM gaskets, seamless interiors, and CIP nozzles facilitate easy cleaning and optimal hygiene, making them ideal for sensitive industries such as dairy, food, and pharmaceuticals.

Efficient Operation & Broad Application

With options for automatic or semi-automatic operation, PLC or manual control, and various heating methods, these vats accommodate mixing, storage, fermentation, and temperature-controlled processes. Equipped with leak-proof and corrosion-resistant properties, they are built for frequent, rigorous industrial use across single or three-phase power supplies.

FAQs of Tank Process Vats:

Q: How do I select the appropriate agitator type for my process vat?

A: The choice of agitator (Anchor, Paddle, or custom) depends on your products viscosity and process objectives. Anchor and Paddle agitators are ideal for gentle mixing or products with moderate viscosity. For unique mixing requirements, custom agitators can be designed as per your process specifications.Q: What are the benefits of using stainless steel (SS304/SS316) in these process vats?

A: Using high-grade SS304 or SS316 offers exceptional corrosion resistance, high durability, and hygiene, which are crucial for the food, dairy, pharmaceutical, and chemical industries. Stainless steel also ensures easy cleaning and a seamless, leak-proof construction.Q: When should insulation like PUF or Glass Wool be chosen for the tank?

A: Insulation, either PUF or Glass Wool, is recommended when temperature retention is vital for your process, such as in fermentation or temperature-sensitive mixing. Select insulation as an option when operating at controlled temperatures up to 120C is required.Q: Where can these process vats be installed, and are they mobile?

A: Our tanks are typically installed floor-mounted and are available in both fixed and portable configurations (with wheels). This flexibility allows easy integration into new or existing production spaces as per workflow needs.Q: What features make these process vats suitable for mixing, storage, and fermentation?

A: Process vats are designed for multipurpose applications, offering seamless finishes for hygiene, rugged construction for durability, and several accessories like temperature gauges and level indicators. You can also opt for heating via steam or electric methods for additional process versatility.Q: How does the cleaning process work for these tanks?

A: Cleaning is straightforward due to their mirror/matt interior surfaces, leak-proof joints, and incorporation of a CIP (Cleaning-In-Place) nozzle. This ensures efficient and thorough sanitation, meeting strict cGMP guidelines especially important in food, dairy, and pharma applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Technology And Equipment Category

Goma pilot scale UHT plant consists of following equipment

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Flash or Indirect UHT

Machine Type : UHT Sterilizer Pilot Scale

Dimension (L*W*H) : Approx. 2500 x 1200 x 2150 mm

Function Type : Mixing Other, Continuous Processing

Vacuum Pan Evaporator

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Other, Industrial Evaporator

Machine Type : Batch Type

Dimension (L*W*H) : Customized

Function Type : Mixing Other, Concentration of Juice

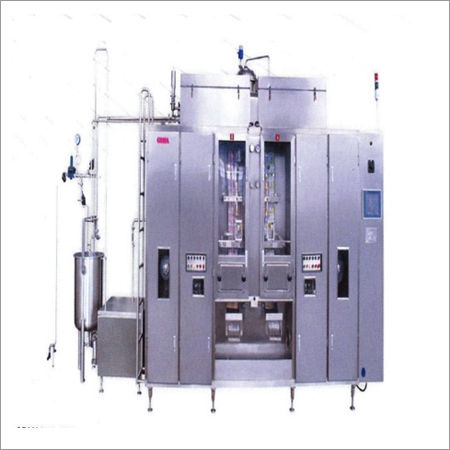

Aseptic Filler

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Other, Aseptic Filler

Machine Type : Aseptic Filling and Packing Machine

Dimension (L*W*H) : 3000 x 1200 x 2100 mm

Function Type : Mixing Other, Filling & Sealing

Yoghurt Cream Pasteuriser

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Other, Yoghurt Cream Pasteuriser

Machine Type : Batch Type

Dimension (L*W*H) : 850 x 650 x 1200 mm

Function Type : Mixing Other, Heating and Pasteurising

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry