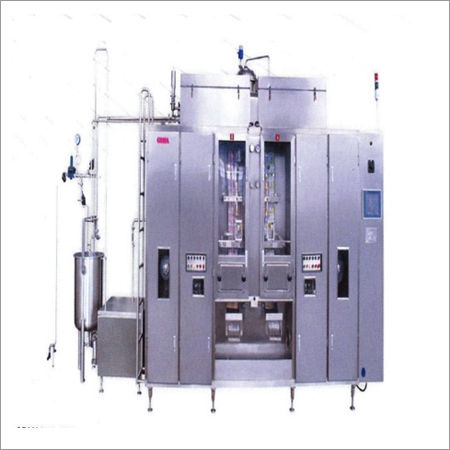

Fruit & Vegetable Processing Plant

MOQ : 1 , , Piece

Fruit & Vegetable Processing Plant Specification

- Heating Method

- Electric/Steam Heating

- Feeding System

- Automatic Conveyor Feeding

- Noise Level

- 70 dB

- Features

- Low Maintenance, CIP (Clean in Place), Hygienic Design

- Automation Grade

- Automatic

- Speed Mode

- Variable

- Operating Temperature

- 5C to 100C

- Power Source

- Electric

- Frequency

- 50/60 Hz

- Machine Type

- Modular Integrated System

- Function Type

- Multi-Function (Washing, Peeling, Cutting, Blanching, Pulping, Packaging)

- Phase

- Three Phase

- Product Type

- Processing Plant

- General Use

- Processing Fruits & Vegetables for Puree, Pulp, Juice, Paste, Dicing, Slicing

- Material

- Stainless Steel

- Type

- Fruit & Vegetable Processing Machinery

- Capacity

- 500 kg/hr to 10,000 kg/hr

- Weight (kg)

- Varies (as per plant size)

- Product Shape

- Rectangular Modular Plant

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control Panel

- Installation Type

- Containerized/Mounted

- Voltage

- 380V - 440V

- Power

- 30-120 kW (customizable)

- Dimension (L*W*H)

- Depend on Capacity (custom built)

- Raw Material

- Stainless Steel (SS 304/316)

- Feature

- Corrosion Resistant, Energy Efficient, Durable

- Color

- Silver/Grey (Stainless Steel Finish)

- Applicable Products

- Tomato, Mango, Guava, Pineapple, Apple, Carrot, etc.

- Cleaning System

- Automatic High-Pressure Washer

- Safety Standard

- CE Certified

- Plant Life Expectancy

- 15+ Years

- Packaging Output

- Aseptic Bag, Bottle, Pouch

- Conveyor Type

- Belt/Screw Conveyor

- Utilities Required

- Electricity, Steam, Water (As Per Specification)

- Installation Assistance

- Available Onsite

- Operator Interface

- Touch Screen HMI

- Water Consumption

- Minimised with Recirculation

- After Sales Service

- Available

- Pulping Efficiency

- Up to 98%

- Sterilization Method

- Continuous Tubular Sterilizer

- Transportability

- Modular & Easily Transportable Units

- Support Documents

- Operation Manual, Process Flow Charts

- Customization

- Yes, Capacity & Design Customizable

Fruit & Vegetable Processing Plant Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Fruit & Vegetable Processing Plant

Developed from 304 grade stainless steel, this Fruit & Vegetable Processing Plant maintains 10 degree C to 200 degree C operating temperature. Its production capacity per hour is around 2000 kg. This machine uses steam based heating source to process fruits and veggies. It has standard accessories like freeze dryer and temperature controlling section. Standard of this Fruit & Vegetable Processing Plant has been verified on the basis of its design precision, service life, mode of processing and user friendliness. This plant maintains hygienic operating mode to keep nutritional value of processed items intact.

Comprehensive Processing Capability

Designed for versatility, the plant automates washing, peeling, dicing, slicing, pulping, and packaging for a variety of fruits and vegetables. Whether youre processing tomatoes for paste or mangoes for puree, the systems modularity and customizable options ensure top performance across different product types. Stainless steel construction guarantees hygienic operation and easy cleaning, further enhanced by built-in Clean-In-Place (CIP) features.

User-Friendly Operation & Intelligent Control

Operation is both intuitive and efficient using the integrated touch screen HMI and advanced PLC control panel. Operators have full control over the processing parameters, including temperature and speed, making adjustments simple and ensuring consistent output quality. The computerized and automatic system reduces manual intervention, minimizes errors, and streamlines the entire production process.

Efficient, Durable, and Energy-Saving Design

Emphasizing sustainability and minimal operational costs, the plant uses a recirculating water system to reduce consumption and energy-efficient mechanisms to lower power requirements. The robust stainless steel frame ensures long-term durability, corrosion resistance, and easy maintenance, supporting continuous operation with minimal down-time for over 15 years.

FAQs of Fruit & Vegetable Processing Plant:

Q: How does the automatic high-pressure washer improve the cleaning process?

A: The automatic high-pressure washer efficiently removes contaminants from fruits and vegetables by utilizing forceful water jets, ensuring maximum cleanliness before processing. It is integrated with a recirculation system, reducing water usage while maintaining hygiene and quality throughout the operation.Q: What types of products can be processed with this plant?

A: This plant can handle a diverse range of fruits and vegetables, including tomatoes, mangoes, guavas, pineapples, apples, and carrots. It is suitable for producing puree, pulp, juice, paste, or diced and sliced products, meeting a wide array of production needs.Q: When is onsite installation support provided?

A: Onsite installation assistance is available upon delivery and commission of the plant. Our expert technicians ensure proper setup and provide initial training, so your operations can commence smoothly and efficiently.Q: Where can the modular plant be installed, and is it easily transportable?

A: The modular and containerized design allows the plant to be installed in various locations, whether at an industrial site or a remote facility. Its structure enables easy transport and quick assembly, adapting conveniently to different production spaces.Q: What is the sterilization process and why is it important?

A: The plant uses a continuous tubular sterilizer that circulates heated fluids at controlled temperatures to eliminate harmful microbes. This process is crucial for ensuring product safety, extended shelf life, and compliance with food safety standards.Q: How does the plant ensure low maintenance and long-term durability?

A: Manufactured from high-grade stainless steel with corrosion-resistant properties, the plant offers easy cleaning and robust structural integrity. Features like Clean-In-Place (CIP), modular components, and energy-efficient technology contribute to trouble-free operation and a life expectancy of over 15 years.Q: What are the benefits of customizable capacity and design?

A: Customization allows the plants design, capacity (500 kg/hr to 10,000 kg/hr), and utilities to be tailored to your specific production requirements, ensuring optimized workflow, maximum efficiency, and scalability for future expansion.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Lab Scale-Pilot Plants Category

Lab UHT With Filling Console

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Heating Method : Indirect Heating

Type : Other, Lab Scale UHT Plant

Automatic : Yes

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry