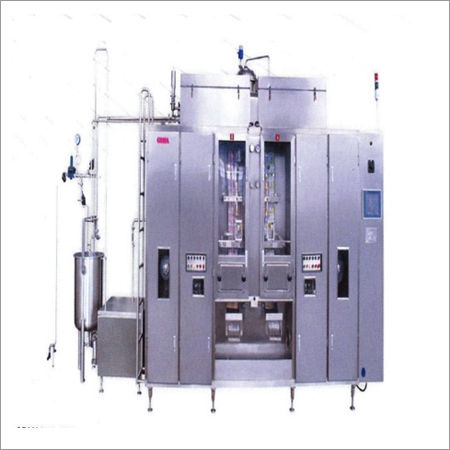

Goma pilot scale UHT plant consists of following equipment

Goma pilot scale UHT plant consists of following equipment Specification

- Automation Grade

- Automatic

- Heating Method

- Indirect Steam or Electric Heating

- Features

- CIP Compatible, Data Logging, Temperature & Pressure Sensors

- Power Source

- Electric

- Phase

- Three Phase

- Speed Mode

- Variable

- Frequency

- 50 Hz / 60 Hz

- Noise Level

- Low

- Feeding System

- Sanitary Positive Displacement Pump

- Machine Type

- UHT Sterilizer Pilot Scale

- Operating Temperature

- Up to 140C

- Function Type

- Continuous Processing

- Product Type

- Pilot Scale UHT Plant

- General Use

- Thermal Processing of Liquid Foods (Milk, Juices, etc.)

- Material

- Stainless Steel

- Type

- Flash or Indirect UHT

- Capacity

- 50-200 Litres Per Hour

- Weight (kg)

- Approx. 1200 kg

- Product Shape

- Rectangular Modular Units

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based with Touch Screen HMI

- Installation Type

- Floor Mounted

- Voltage

- 380V / 415V

- Power

- 12-20 kW (Depending on configuration)

- Dimension (L*W*H)

- Approx. 2500 x 1200 x 2150 mm

- Raw Material

- Stainless Steel 304/316

- Feature

- Pilot Scale UHT, Compact Design, Energy Efficient

- Color

- Metallic Silver

- Operator Display

- Digital Process Monitoring

- Water Requirement

- Approx. 200 L/hr for Cooling/CIP

- Applicable Standards

- Meets CE and GMP Requirements

- Product Contact Surfaces

- Mirror Finish SS 316

- Data Recording

- USB or Ethernet Download

- Cooling Section

- Plate/Tube Heat Exchanger with Chilled Water/Glycol

- Piping & Connections

- Hygienic SS Tubing with Tri-clamp Fittings

- Processing Media

- Milk, Flavored Milk, Dairy Mixes, Juices, Liquid Foods

- Scalability

- Suitable for R&D and Small-batch Production

- Sterilization Hold Time

- 1-300 seconds adjustable

- Sterilization Capability

- Microbial and Enzyme Inactivation

- Compressed Air Requirement

- 6 Bar (if pneumatic valves used)

- Sampling Provision

- Aseptic Sampling Valve

- Safety Features

- Overload, Over-temperature, Interlocks, Emergency Stop

- Homogenizer

- High Pressure, Optional Integration

- Mobility

- Mounted on Lockable Caster Wheels

- Cleaning System

- Automatic CIP (Clean-in-Place)

- Accessories Included

- Product Feed Tank, Balance Tank, Flowmeter, Control Panel

Goma pilot scale UHT plant consists of following equipment Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Goma pilot scale UHT plant consists of following equipment

Specification

| Installation space required | LBH-7000 * 6000 * 4900 mm |

| Machine Dimension | LBH-3800 * 2100 * 3140mm |

| Electrical Power | 38 kw |

| Compressed Air | 0.6 Mpa |

| H2 O2 | 1 L / Time |

| Capacity (Pouches/ Hr) | 4500-9000 Pouches/ Hr (2 Heads) |

| Filling Volume (ml) | 100ml-1000 ml ( Adjustable) |

| Product Range | Skimmed Milk,Toned Milk |

Advanced Processing Versatility

This UHT plant supports flash or indirect sterilization for a wide range of liquid foods, including dairy products, juices, and other mixes. Operators can easily adjust sterilization hold times and temperatures to accommodate different product needs, ensuring both microbial and enzyme inactivation as required.

User-Friendly Operation and Automation

Equipped with a PLC-based control system and touch screen HMI, process parameters are easily monitored and adjusted. Automatic cleaning-in-place (CIP), hygienic design, and overload/interlock protections simplify operation and maintenance, presenting a straightforward workflow for both R&D and production staff.

Comprehensive Safety and Compliance

Safety is paramount with overload, over-temperature protections, emergency stops, and interlocks. The unit meets CE and GMP standards, suitable for international operations and food safety compliance, further reinforced by hygienic stainless steel construction and precision fittings.

Robust Data Management and Scalability

Integrated USB/Ethernet data download, continuous data logging, and variable capacity (50200 L/hr) support experimental, scale-up, and documentation needs. Modular construction with caster wheels enables flexible installation and operation across diverse production environments.

FAQs of Goma pilot scale UHT plant consists of following equipment:

Q: How is product sterilization achieved in the Goma pilot scale UHT plant?

A: Product sterilization is accomplished via indirect or flash UHT treatment, allowing flexible sterilization hold times between 1 and 300 seconds. The process ensures effective microbial and enzyme inactivation using high-pressure homogenization and precise temperature management up to 140C.Q: What types of liquids can be processed and what capacities are supported?

A: The UHT plant effectively processes milk, flavored milk, dairy mixes, juices, and various liquid foods. It is designed for pilot or small-scale production, supporting throughput from 50 to 200 liters per hour, making it suitable for both R&D and small-batch commercial applications.Q: When and how can data from the UHT system be recorded and retrieved?

A: All process data is continuously logged and can be downloaded via USB or Ethernet at any point after or during production runs. This feature simplifies research documentation and quality control, ensuring traceability and process reproducibility.Q: Where can the Goma pilot scale UHT plant be installed and operated?

A: With its compact modular design and lockable caster wheels, the plant is floor-mounted and easily moved. Meeting CE and GMP standards, it is appropriate for installation in laboratories, pilot plants, and small-scale production facilities globally.Q: What is the cleaning process and how is operator safety ensured?

A: The system features a fully automatic Clean-in-Place (CIP) function, utilizing hygienic piping and mirror-finish SS316 contact surfaces. Operator safety is further ensured through overload/over-temperature protections, emergency stops, safety interlocks, and digital monitoring.Q: How does the control system enhance process efficiency?

A: A PLC-based control system with touch screen HMI enables precise, easy adjustments of all critical process parameters such as temperature, hold time, and pressures. Real-time monitoring boosts efficiency, reduces manual handling, and minimizes error risk.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Technology And Equipment Category

UHT Sterilizer

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Installation Type : Other, Upright / Floor Mounted

Power Source : Electric

Features : CIP System, Accurate Temperature Control, Low Maintenance

Automation Grade : Fully Automatic

Vacuum Pan Evaporator

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Installation Type : Other, Floor Mounted

Power Source : Electric

Features : Energy Efficient, Durable, Easy Operation

Automation Grade : SemiAutomatic

Tank Process Vats

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Installation Type : Other, Floor Mounted

Power Source : Electric

Features : Seamless Finish, Rugged Construction, High Durability

Automation Grade : SemiAutomatic / Automatic

Plate Heat Exchanger Chiller

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Installation Type : Other, Floor Mounted

Power Source : Electric

Features : Easy Maintenance, Energy Efficient

Automation Grade : Automatic

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry