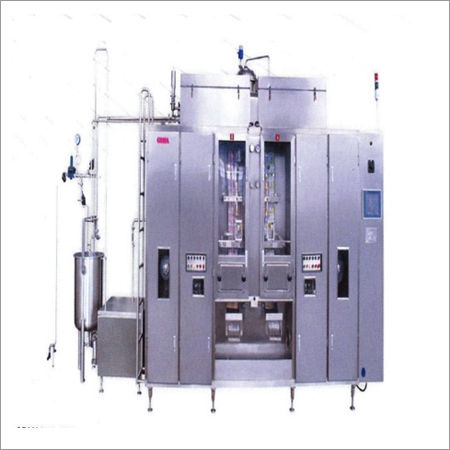

Plate Heat Exchanger Chiller

Plate Heat Exchanger Chiller Specification

- Power Source

- Electric

- Machine Type

- Cooling Machine

- Operating Temperature

- -5C to 40C

- Features

- Easy Maintenance, Energy Efficient

- Frequency

- 50 Hz

- Function Type

- Cooling

- Feeding System

- Pump Fed

- Automation Grade

- Automatic

- Phase

- Three Phase

- Noise Level

- 60 dB

- Speed Mode

- Variable

- Product Type

- Plate Heat Exchanger Chiller

- General Use

- Industrial Cooling

- Material

- SS304

- Type

- Chiller

- Capacity

- 20 TR

- Weight (kg)

- 340

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Installation Type

- Floor Mounted

- Voltage

- 380 V

- Power

- 7.5 kW

- Dimension (L*W*H)

- 1200 x 700 x 1100 mm

- Raw Material

- Stainless Steel

- Feature

- High Efficiency, Compact Design

- Color

- Silver

- Max Flow Rate

- 45 m³/h

- Cooling Capacity

- 70 kW

- Connection Size

- 2 Inch

- Frame Material

- Galvanized Steel

- Heat Transfer Area

- 40 m²

- Insulation Thickness

- 40 mm

- Refrigerant

- R407c/R134a

- Application

- Process Cooling, HVAC, Food & Beverage

- Working Pressure

- 10 Bar

- Plate Material

- 316L Stainless Steel

- Compressor Type

- Scroll

Plate Heat Exchanger Chiller Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Plate Heat Exchanger Chiller

High-Efficiency Cooling Solution

This chiller combines advanced plate heat exchanger technology with scroll compressors to deliver consistent, high-performance cooling for demanding environments. Its energy-efficient operation minimizes operational costs, making it an ideal choice for factories, laboratories, and processing plants requiring precision temperature control.

Durable and Compact Design

Crafted from 316L stainless steel and galvanized steel, this chiller withstands harsh industrial conditions. The compact rectangular shape (1200 x 700 x 1100 mm) and floor-mounted installation facilitate space optimization, enabling seamless integration into new or existing facilities.

Automatic and Computerized Operation

Equipped with a PLC-based control system and variable speed mode, the chiller automates temperature adjustment and flow management, enhancing operational efficiency and reducing the need for manual supervision. The computerized controls ensure precise cooling performance and safety.

FAQs of Plate Heat Exchanger Chiller:

Q: How does the plate heat exchanger chiller achieve high energy efficiency?

A: This chiller utilizes advanced plate heat exchanger technology, combined with scroll compressors and variable speed modes, to maximize heat transfer while minimizing power consumption. Insulation and PLC-based automated controls further enhance its energy efficiency.Q: What maintenance procedures are recommended for this chiller model?

A: Thanks to its easy maintenance design, periodic cleaning of the stainless steel plates and inspection of the pump-fed system suffice to keep the unit in optimal condition. Additionally, scheduled performance checks of the PLC system are recommended.Q: When should this chiller be installed in an industrial process?

A: Install the chiller when consistent and reliable cooling is critical for production, such as in food & beverage, HVAC systems, and process cooling. It is ideal for operations requiring efficient temperature management and automatic control capabilities.Q: Where can the plate heat exchanger chiller be effectively used?

A: This machine is suited for industrial environments, including factories, laboratories, food processing units, and HVAC plants. Its compact, floor-mounted design allows flexibility in placement across different facility layouts.Q: What benefits does the PLC-based control system offer in this chiller?

A: The PLC-based system enables fully automatic operation, real-time monitoring, precise temperature control, and quick troubleshooting. This reduces manual intervention, increases operational safety, and streamlines system management.Q: How is the chillers feeding system operated?

A: The unit features a pump-fed system that efficiently distributes coolant through stainless steel heat exchanger plates, facilitating uniform cooling and optimal thermal performance under variable operating conditions.Q: What applications are supported by this chillers design and features?

A: Compatible with process cooling, HVAC, food & beverage industries, the chillers robust construction and versatile operating temperature range make it suitable for a wide spectrum of industrial cooling tasks in India and global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Technology And Equipment Category

Aseptic Filler

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Speed Mode : other, Variable Frequency Drive (VFD)

Noise Level : 70 dB

Installation Type : Other, Floor Mounted

Phase : Three Phase

Vacuum Pan Evaporator

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Speed Mode : other, Single

Noise Level : Low

Installation Type : Other, Floor Mounted

Phase : Three Phase

S.S. Storage Tanks Silos Cooling tanks

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Speed Mode : other, Variable (Depends on Cooling Process)

Noise Level : Low

Installation Type : Other, Onsite Installation

Phase : Single Phase / Three Phase

Yoghurt Cream Pasteuriser

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Speed Mode : Variable

Noise Level : Low

Installation Type : Other, Floor Mounted

Phase : Single Phase

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry