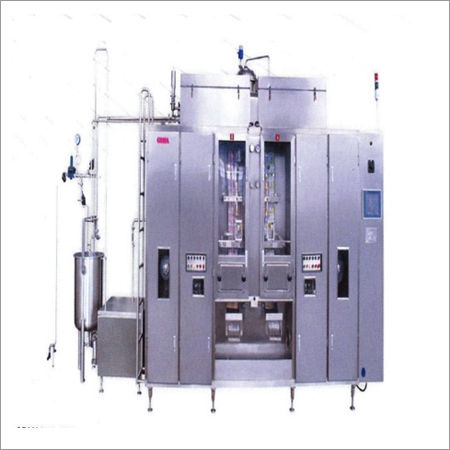

Reactor Cleaning System

Reactor Cleaning System Specification

- Tank Capacity

- 50-200 Liters (solution tank)

- Suction Power

- High efficiency self-priming pump

- Power Source

- Electric motor operated pump

- Control System

- Digital PLC-based control panel

- Accessories

- Set of brushes, hose pipes, control panel, solution tank

- Equipment Type

- Reactor Cleaning System

- Pressure Ratings

- Upto 200 Bar

- Features

- Corrosion resistant, heavy duty construction, mobile skid mounted, self-cleaning

- Brush Types

- Rotary and static nozzle brush attachments

- Connectivity Type

- Hose pipe with quick release couplings

- Water Flow Rate

- 20-50 LPM

- Material

- Stainless Steel

- Type

- Automatic Reactor Cleaning System

- Condition

- New

- Fuel Type

- Electric

- Use

- Industrial reactor and vessel cleaning

- Cleaning Process

- Hydro-jetting and high pressure spray

- Cleaning Type

- In-Place Cleaning (CIP)

- Capacity

- Customizable (commonly 250-5000 Liters)

- Voltage

- 220415 V

- Safety Features

- Automatic shut-off, over-pressure protection

- Mobility

- Trolley-mounted for easy transport

- Noise Level

- <70 dB

- Cleaning Lance Length

- Adjustable up to 2 meters

- Application Area

- Chemical, pharmaceutical, and food processing industries

- Ambient Operating Temperature

- 5C 45C

- Surface Finish

- Polished

Reactor Cleaning System Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Reactor Cleaning System

Advanced Cleaning Technology

The Reactor Cleaning System utilizes high-pressure hydro-jetting and spray techniques to remove residues from internal surfaces efficiently. Adjustable cleaning lance lengths and diverse brush attachments allow for flexible cleaning, ensuring optimal results for reactors and vessels in various industrial sectors.

Mobility and User-Friendly Design

Trolley-mounted and skid-based, the system offers easy movement between different work areas. Quick release hose couplings and ergonomic controls simplify setup, making it ideal for fast-paced operations in chemical, pharmaceutical, and food processing plants.

Safety and Control Features

The unit integrates automatic shut-off, over-pressure protection, and a digital PLC control panel for enhanced operator safety. These safeguards, alongside heavy-duty stainless steel construction and corrosion resistance, ensure reliable day-to-day operations, even in demanding environments.

FAQs of Reactor Cleaning System:

Q: How is the Reactor Cleaning System operated during cleaning processes?

A: The Reactor Cleaning System operates using a digital PLC-based control panel, which manages all cleaning parameters. The process involves hydro-jetting and high-pressure spray with adjustable cleaning lances and brush attachments to clean reactor interiors efficiently.Q: What are the benefits of using an automatic reactor cleaning system for industrial applications?

A: Using this automatic cleaning system reduces manual labor, ensures thorough cleaning of complex surfaces, and minimizes downtime. Safety features such as automatic shut-off and over-pressure protection further enhance operational reliability in industrial settings.Q: When should reactor cleaning be performed using this system?

A: Reactor cleaning should be conducted according to your process schedule, typically between production batches or during maintenance intervals to remove accumulations and prevent contamination. The systems in-place cleaning feature allows for quick, safe, and routine operations.Q: Where can the Reactor Cleaning System be deployed within a facility?

A: The system is mobile and trolley-mounted, allowing deployment across multiple areas in chemical, pharmaceutical, or food processing plants. Its hose pipe connectivity with quick release couplings facilitates flexible installation in various reactor locations.Q: What cleaning accessories are provided with the system?

A: Each unit is supplied with rotary and static nozzle brush attachments, hose pipes, a control panel, and a solution tank, offering comprehensive tools for diverse reactor sizes and residues.Q: How does the system ensure operator safety during use?

A: Operator safety is maintained through automatic shut-off, over-pressure protection, and durable stainless steel construction. The systems PLC panel allows for precise control and monitoring, reducing risk during high-pressure operations.Q: What is the process for maintaining and cleaning the system itself?

A: The Reactor Cleaning System features a self-cleaning design and corrosion-resistant materials. Maintenance typically involves regular inspection of brushes, hoses, pumps, and the solution tank, with minimal downtime due to its heavy-duty and mobile construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Pressure Cleaning Packages Category

High Pressure Cleaner

Minimum Order Quantity : 1 Piece

Voltage : 400~440 Volt (v)

Capacity : TBA m3/hr

Control System : Manual

Material : Stainless Steel

Mobile Decontamination System

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220240V AC

Capacity : 90100 square meters per hour

Control System : Digital Onboard Control Panel

Material : Other, Stainless Steel and HighGrade Polymer Body

Multi Jet Washing System

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220440 V

Capacity : 5002000 Units per Hour

Control System : PLC Controlled

Material : Other, Stainless Steel

Coke Oven Door Cleaning System

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Capacity : Up to 200 Doors/Day

Control System : PLC Controlled

Material : Other, Mild Steel (MS), Stainless Steel

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry