Skid Mounted Plant

Skid Mounted Plant Specification

- Power Source

- Electric

- Features

- Compact Design, Easy Relocation, Integrated Control

- Operating Temperature

- 0C to 80C

- Automation Grade

- Fully Automatic

- Function Type

- Continuous / Batch Operation

- Noise Level

- < 70 dB

- Machine Type

- Industrial Skid Package

- Phase

- Three Phase

- Frequency

- 50/60 Hz

- Feeding System

- Automatic (Pump/Gravity)

- Speed Mode

- Variable (VFD Controlled)

- Product Type

- Process Plant Skid

- General Use

- Liquid Processing, Chemical Mixing, Water Treatment, Other Process Industries

- Material

- Mild Steel (MS) or Stainless Steel (SS 304/316)

- Type

- Prefabricated Modular Plant

- Capacity

- Custom 500 LPH to 10000 LPH (as per requirement)

- Product Shape

- Rectangular Skid Frame

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Installation Type

- Skid Mounted

- Voltage

- 415 V

- Power

- 7.5 kW

- Dimension (L*W*H)

- Custom as per capacity (approx. 3500mm x 1800mm x 2200mm)

- Raw Material

- Mild Steel / Stainless Steel

- Color

- Industrial Grey (customizable options available)

Skid Mounted Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Skid Mounted Plant

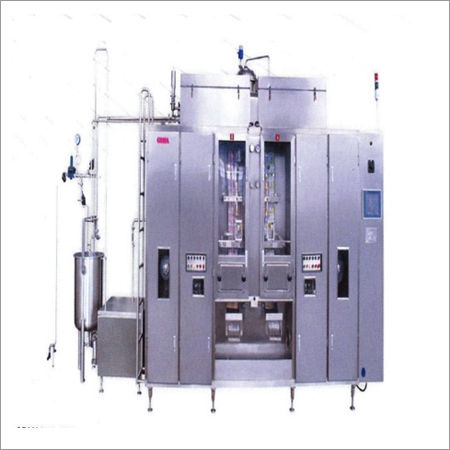

Skid Mounted Plant

We are one of the prominent manufacturer and supplier of Skid Mounted Plant. Offered product is tested on various quality parameters before being delivered to the market. It is compact in size, easy to operate and requires less maintenance. In order to cater the different demands of our customers, we offer Skid Mounted Plant in different capacities and specifications. It is widely used for processing of milk, pulp, yoghurt, creams, beverages and various other items.

Various Applications:

Process module : Capacity 20 LPH TO 10000 LPH

- Liquid Milk

- Flavoured Milk

- Ice-cream

- Cheese Milk

- Soya Milk

- Fruit Juice

Process Module (Tubular Type) : Capacity 20 LPH TO 10000 LPH

- Cream

- Drinking Yoghurt

- Necter Beverages

- Pulp etc

Salient Features:

- Compact in Design

- Factory fitted & Tested

- Space Saving

- Easy Installation

- Ready to start

- Less Maintainance

- Easy to operate

Model Selection Chart

| Model | Capacity LPH |

| LAB | 20 |

| GMD - 1 | 100 |

| GMD - 3 | 300 |

| GMD - 5 | 500 |

| GMD - 10 | 1000 |

| GMD - 20 | 2000 |

| GMD- 30 | 3000 |

Advanced Automation and Control

This skid-mounted plant is engineered with state-of-the-art PLC-based control for full automation, ensuring precise process regulation and minimal manual intervention. Users benefit from variable frequency drives enabling speed adjustments, while the integrated system streamlines monitoring and operation in industrial environments.

Robust Construction and Customization

Built from high-quality mild steel or stainless steel (SS 304/316), the plant offers flexibility in both material and color. Its modular rectangular skid frame accommodates custom dimensions based on required capacity, ranging from 500 to 10,000 liters per hour, making it adaptable for diverse industrial applications.

Plug-and-Play Installation

The skid-mounted configuration enables straightforward installation and relocation, requiring minimal on-site assembly. Its design is ideal for rapid deployment in new or expanding facilities, reducing downtime and accelerating time to production. The system operates efficiently on a 415 V, three-phase electric power source.

FAQs of Skid Mounted Plant:

Q: How is the Skid Mounted Plant installed, and can it be relocated easily?

A: The plant arrives prefabricated on a rectangular skid frame, allowing for quick installation without extensive on-site construction. Its compact, modular design supports easy relocation within a facility or to a new site as operational needs change.Q: What processes and industries are best suited for this Skid Mounted Plant?

A: This plant is ideal for liquid processing, chemical mixing, water treatment, and other industrial process applications across sectors like pharmaceuticals, chemicals, food and beverages, and more.Q: When is computerized, fully automatic operation beneficial for processing plants?

A: A computerized, fully automatic system benefits operations by ensuring consistent quality, reducing labor requirements, and enhancing safety. The PLC-based controls facilitate continuous or batch processing with minimal manual intervention.Q: Where does the plant source its power, and is it suitable for industrial environments?

A: The plant operates on a 415 V, three-phase electric supply and is engineered to withstand industrial conditions, with corrosion-resistant materials and a low noise level (<70 dB).Q: What are the advantages of the integrated PLC-based control system?

A: The PLC-based control system offers precise process management, real-time monitoring, and easy programming for various recipes or production parameters, allowing seamless adaptation to diverse processing requirements.Q: How is the plants capacity determined and can it be customized?

A: Capacity ranges from 500 LPH to 10,000 LPH, and the dimensions of the plant are tailored to specific client requirements. Customization ensures the plant is appropriately sized for the desired throughput and available space.Q: What are the benefits of using a variable frequency drive (VFD) and automatic feeding system?

A: The VFD allows operators to control process speed for optimal performance, while the automatic feeding system enhances efficiency and ensures consistent input, reducing processing downtime and improving product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dairy & Food Processing Machinery Category

Skid Mounted Spray Dryer

Minimum Order Quantity : 1 Piece

Heating Method : Steam / Electric / Gas

Features : Sanitary Construction, User Friendly Interface, Rapid Installation

General Use : Industrial Drying Applications

Color : Other, Silver / Metallic

Lab Homogenisers

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Heating Method : None

Features : Compact Design, Energy Efficient, User Friendly

General Use : Mixing, Homogenizing, Emulsifying

Color : Other, White & Blue

Skid Mounted Process Module

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Heating Method : Electrical/Steam Jacket

Features : Compact design, High efficiency modular system

General Use : Chemical/Pharma/Oil & Gas Applications

Color : Other, Industrial Grey/Blue

Skid Mounted Evaporator

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Heating Method : Steam Heating

Features : Compact Design, Corrosion Resistant, Energy Efficient

General Use : Effluent, Wastewater, Distillation Processes

Color : Other, Silver / Metallic

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry