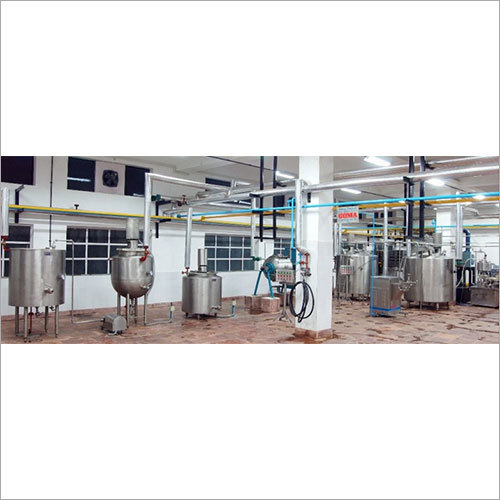

Milk Processing Plant

Milk Processing Plant Specification

- Temperature Range

- 4C to 72C

- Usage & Applications

- Dairy Plants, Milk Chilling & Pasteurization

- Accessories

- Milk Receiver, Pasteurizer, Storage Tanks, Pumps

- Motor Power

- 5 HP

- Production Capacity

- Up to 10,000 Liters/Day

- Efficiency (%)

- 98%

- Driven Type

- Electric

- Frequency

- 50 Hz

- Model No

- MPPU-4000

- Speed

- 1400 RPM

- Installation Guideline

- On-Site Support Provided

- Automation Grade

- Fully Automatic

- Type

- Milk Processing Plant

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric Motor

- Voltage

- 380-440 V

- Power

- 15 kW

- Weight (kg)

- 2200 kg

- Dimension (L*W*H)

- 4200 x 1500 x 2300 mm

- Color

- Silver

- Capacity

- 1000-5000 Liters/Hour

- Features

- Corrosion Resistant, High Durability, Energy Saving

- Machine Type

- Milk Pasteurizer & Processing Unit

- Power Consumption

- 12-18 kW/hr

- Surface Finish

- Polished

- Utility Requirement

- Electricity, Water Supply

- Maintenance Requirement

- Low Maintenance

- Required Water Pressure

- 2-4 Bar

- Water Consumption

- 0.3 m³/hr

- Insulation

- PU Foam Insulation

- Heat Exchanger Type

- Plate Heat Exchanger

- Noise Level

- Less Than 60 dB

- Environmental Compliance

- Meets ISO & CE Standards

- Safety Features

- Emergency Stop, Overload Protection

- Operation Panel

- Touch Screen HMI

- Cooling System

- Integrated Chiller Unit

- Service Support

- Available Nationwide

- Spare Parts Provided

- Yes

- Sanitization System

- CIP (Clean-In-Place) Automated

Milk Processing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Milk Processing Plant

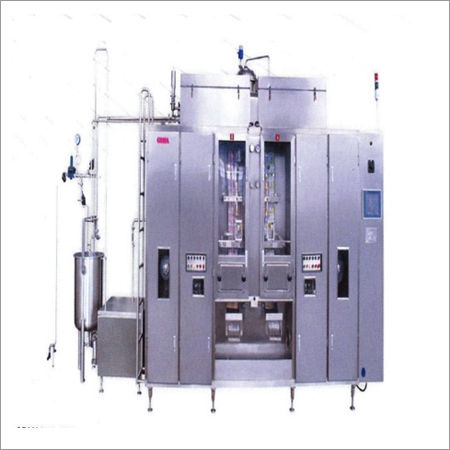

Advanced Integrated Cooling System

This milk processing unit uses a chiller integrated with a plate heat exchanger for precise temperature control, maintaining milk quality from 4C to 72C. Enhanced PU foam insulation ensures minimal heat loss, energy savings, and stable production output, which greatly benefits dairies requiring consistent chilling and pasteurization cycles.

Automated Sanitization for Hygiene

Our Clean-In-Place (CIP) automated system sanitizes all internal components efficiently, eliminating the need for manual cleaning and reducing downtime. This integration supports strict hygiene standards while meeting ISO & CE requirements for safe dairy processing and packaging.

Easy Operation and Reliable Safety

The touch screen HMI operation panel provides intuitive control over all processes, while advanced PLC-based automation ensures reliable and seamless functionality. Safety features such as emergency stop and overload protection safeguard operators, making daily operations worry-free and secure.

FAQs of Milk Processing Plant:

Q: How does the integrated chiller unit benefit milk processing operations?

A: The chiller maintains precise temperatures during milk chilling and pasteurization, ensuring product safety and extending shelf life. This efficient cooling system optimizes energy consumption and supports high production capacity up to 10,000 liters per day.Q: What is the cleaning process for this milk processing plant?

A: The plant features a CIP (Clean-In-Place) automated sanitization system that thoroughly cleans internal surfaces without disassembly, maintaining hygiene and reducing downtime between production runs.Q: Where is the installation support available for this plant?

A: On-site installation guidance is included, with nationwide service support across India. Experienced engineers assist with setup, training, and ongoing technical support to ensure smooth operation.Q: What are the advantages of the PLC-based control system and touch screen HMI?

A: The PLC-based control and touch screen HMI enable real-time monitoring, simplified adjustments, and enhanced operational safety, allowing operators to manage the entire process efficiently and respond swiftly to any issues.Q: When should routine maintenance tasks be performed on the machine?

A: The plant has low maintenance needs. Basic inspections and CIP cleaning cycles can be scheduled according to usage intensity, with support for spare parts and nationwide service to address any maintenance requirements promptly.Q: What utilities and environmental requirements does the plant have?

A: It requires a stable electricity supply (380-440V), water at 2-4 Bar pressure, and meets international environmental standards (ISO & CE), ensuring compliance for both domestic and export operations.Q: Can this milk processing plant handle both chilling and pasteurization processes?

A: Yes, the machine is designed for milk chilling and pasteurization, utilizing its integrated chiller, plate heat exchanger, and automated controls to deliver optimal results for dairy plants and large-scale milk producers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dairy Processing Category

Milk Pasteurizer Plant

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Milk Pasteurizer Plant

Efficiency (%) : 95%

Production Capacity : As per plant model

Material : Stainless Steel (SS 304/316)

Paneer Cheese Plant

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Paneer Cheese Plant

Efficiency (%) : Above 95%

Production Capacity : 5002000 Kg/Day

Material : Stainless Steel

Mini Dairy Plant

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Mini Dairy Plant

Efficiency (%) : Above 90%

Production Capacity : 1000 LPD

Material : Stainless Steel

Traditional Indian Sweets

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Traditional Indian Sweets

Efficiency (%) : 100% Manual Efficiency

Production Capacity : Varies by sweet & batch size

Material : Milk, Sugar, Ghee, Cardamom, Dry Fruits

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry