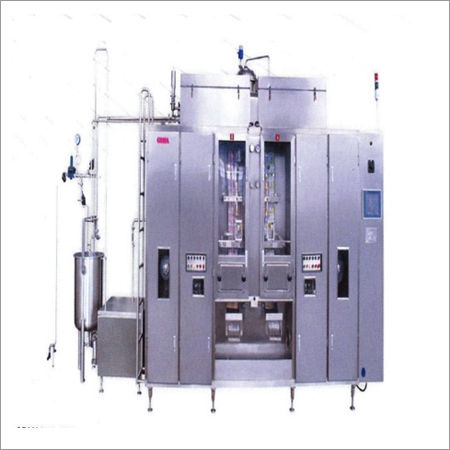

Sanitary Pumps

Price 19000 INR/ Piece

Sanitary Pumps Specification

- Type

- Sanitary Pump

- Material

- Stainless Steel

- Capacity

- 500 5000 LPH

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220V

- Frequency (MHz)

- 50Hz

- Size

- Standard

- Weight

- 25 kg (approx.)

- Dimension (L*W*H)

- 450 x 250 x 350 mm

- Mounting

- Base Plate Mounted

- Seal Type

- Mechanical Seal

- Flow Range

- Adjustable

- Noise Level

- Low

- Max Pressure

- 6 Bar

- Pump Head Material

- SS316

- Max Temperature

- 95C

- Vibration Level

- Minimal

- Motor Power

- 0.75 3 HP

- Pump Type

- Centrifugal / Positive Displacement

- Cleaning

- CIP / SIP Compatible

- Inlet/Outlet Connection

- Tri-clamp / DIN / SMS

- Surface Finish

- Hygienic, Polished

- Application

- Food, Dairy, Pharmaceutical, Beverage

Sanitary Pumps Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Sanitary Pumps

This single stage Sanitary Pump supports self priming technology based CIP cleaning technique. Made of 316L/304 grade stainless steel, this pumping system uses advanced motor for its operation. Driven by electricity, it has double or single sealing arrangement. This Sanitary Pump uses aseptic or flange type or clamped or threaded inlet/outlet connecting parts. Its approximate flow rate is 40 m3/h and maximum suction capacity is 8/M. Standard of this pumping system has been verified on the basis of its diameter, performance, working life and mode of operation.

Specifications

| Max Flow Rate | 50000LPH |

| Head | 50 MWC |

| Model | GCP |

| Brand | Goma |

Precision Hygiene and Safe Operation

Designed with SS316 stainless steel pump heads and a hygienic polished surface, our pumps ensure compliance with safety regulations for sensitive processes. The mechanical seal minimizes risk of leaks, and operation is smooth, with minimal vibration and low noise. These features make our pumps ideal for environments that demand stringent hygiene such as food and pharmaceutical production.

Reliable and Versatile Performance

Whether used in dairy, beverage, or pharmaceutical industries, our sanitary pumps support a wide range of applications. The adjustable flow rate and compatibility with CIP/SIP cleaning methods ensure hassle-free operation and maintenance. With a robust motor (0.753 HP), they handle pressures up to 6 Bar and temperatures up to 95C, powered by 220V/50Hz supplyall while maintaining steady performance and longevity.

FAQs of Sanitary Pumps:

Q: How does the pump ensure sanitary conditions during food and pharmaceutical processing?

A: The pump is constructed with SS316 stainless steel and features a hygienic, polished surface finish, which resists contamination and facilitates cleaning. Its design supports quick disassembly for cleaning, and compatibility with CIP/SIP systems enables thorough in-place sterilization after each use.Q: What types of applications are these sanitary pumps suitable for?

A: These pumps are ideal for food, dairy, beverage, and pharmaceutical industries, where hygiene, low noise, and reliable flow rates are essential. Their versatility comes from adjustable flow capacity, robust sealing, and ability to handle various liquid products in these sectors.Q: When should I choose a centrifugal pump versus a positive displacement pump?

A: A centrifugal pump is best for transferring low-viscosity fluids at higher flow rates, while a positive displacement pump excels with viscous, shear-sensitive, or particulate-rich fluids. Selection depends on the specific product and required process parameters in your production line.Q: Where can the pump be installed, and what are its mounting requirements?

A: The pump is base plate mounted, offering stability on production floors. Its compact dimensions (450 x 250 x 350 mm) and lightweight design (approx. 25 kg) facilitate installation in constrained spaces commonly found in process plants.Q: What is the cleaning process for the pump?

A: The pump supports both CIP (Clean-In-Place) and SIP (Sterilize-In-Place) methods, ensuring efficient internal surface cleaning without disassembly. Operators can run cleaning cycles using appropriate cleaning solutions or steam for sterilization, keeping downtime minimal.Q: How does using this sanitary pump benefit my production process?

A: It provides consistently hygienic operation, adjustable flow rates from 500 to 5000 LPH, and low maintenance with mechanical seals. Its low-noise and minimal-vibration performance creates a safer, more comfortable work environment, while easy cleaning ensures compliance with regulatory standards.Q: What connections and electrical specifications should I be aware of during installation?

A: You can select tri-clamp, DIN, or SMS inlet/outlet connections based on your piping system. The pump operates on a 220V power supply at 50Hz frequency, matching standard industrial electrical setups in India and many other regions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Main Processing Equipments Category

10 KLPH Skid Processing Module

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Weight : 2100 kg (approx.)

Computerized : Yes

Type : Skid Processing Module

Automatic Grade : Automatic

Cheese Paneer Vat Press Hoops

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 50150 kg

Computerized : No

Type : Cheese Paneer Vat Press Hoops

Automatic Grade : Other, Manual/SemiAutomatic

Plate Heat Exchanger-Chiller

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 180 kg

Computerized : No

Type : Plate Heat ExchangerChiller

Automatic Grade : Automatic

Yogurt-Cream Pasteurized

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 1 kg

Computerized : No

Type : YogurtCream Pasteurized

Automatic Grade : Manual

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry