High Pressure Homogenizer

High Pressure Homogenizer Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

- Main Domestic Market

- All India

About High Pressure Homogenizer

With the backing of an extensive experience of almost 4 decades & after meticulous R&D, Goma has now launched New Generation Homogenizers with advanced technology & higher pressures up to 2000 bar.

Specification

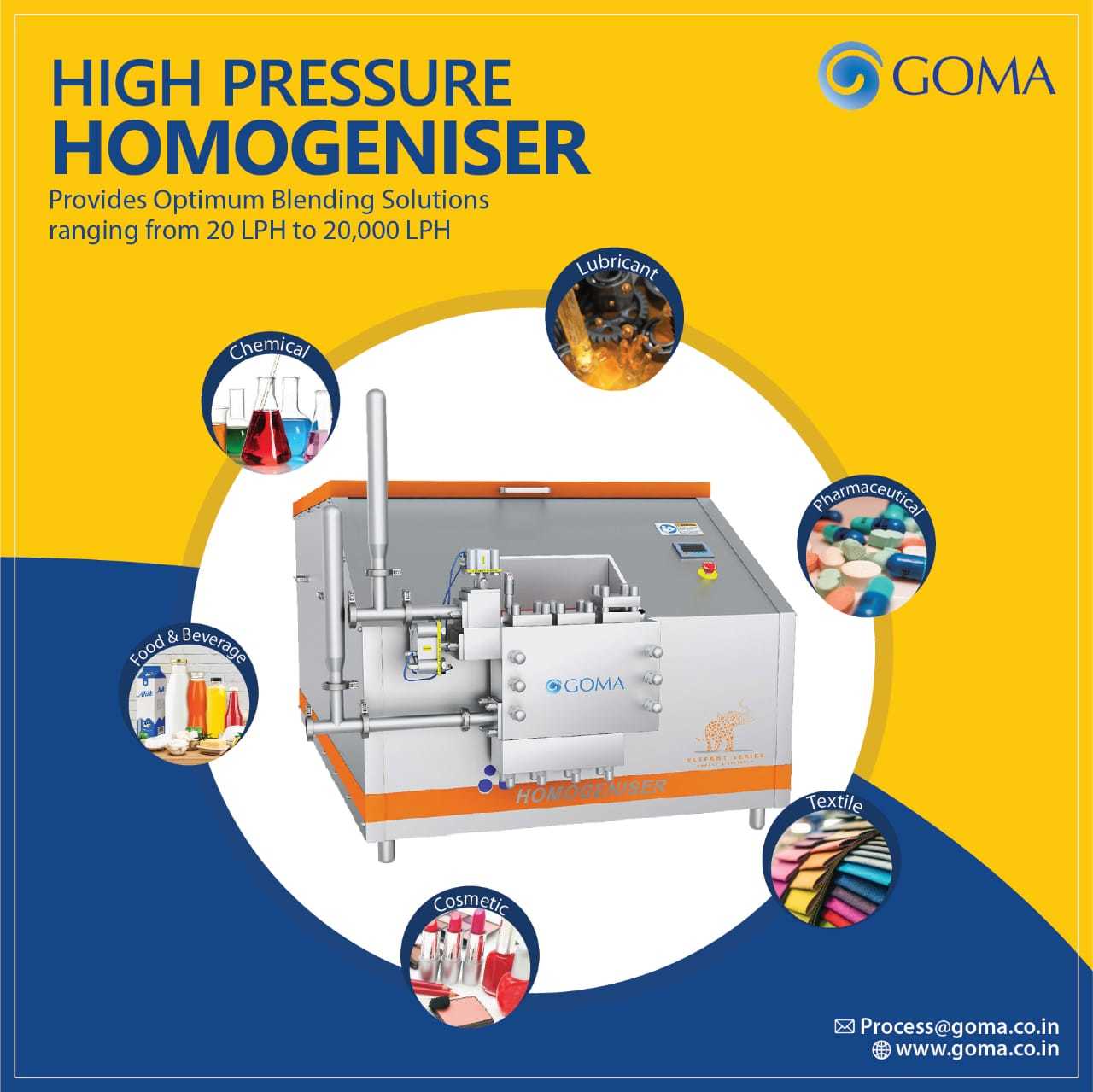

| Capacity (litres/hour) | 100-1000 litres/hour, 20 to 30000 LPH, 1000-5000 litres/hour, 0-100 litres/hour, 1000-10000 litres/hour, >10000 litres/hour |

| Pressure | 100-150 Bar, >250 Bar, 150-200 Bar, 0-100 Bar, 200-250 Bar |

| Brand | GOMA |

| Automation Grade | Automatic |

| Condition | New |

| Application | Chemicals, Pharmaceuticals, cosmetics , paints, Food Processing |

| Plunger Pump | High Pressure triplex/ Quin Tuplex plunger pump. |

| Operated | Manual / Hydraulic |

Advanced Control and Productivity

Featuring a PLC-based control system and computerized operation, this homogenizer simplifies process management, maintaining consistent output quality. Its wide capacity range supports versatile usage across varied industries, from food to cosmetics, ensuring adaptability and productivity.

Durable and Hygienic Construction

Made entirely of stainless steel, the homogenizer resists corrosion and promotes hygienic operations, ideal for demanding environments. The free-standing installation allows for easy integration into different production layouts, enhancing both safety and efficiency.

FAQs of High Pressure Homogenizer:

Q: How does the PLC control system enhance the homogenization process in this machine?

A: The PLC control system automates critical operations, allowing precise regulation of homogenization parameters. This results in consistently uniform product quality, minimizes errors, and enables real-time process monitoring for increased reliability.Q: What types of materials can be processed using this high pressure homogenizer?

A: This homogenizer is designed to handle a variety of substances, including liquids, emulsions, and suspensions across industries like food, pharmaceuticals, and chemicals, thanks to its wide capacity range and stainless steel construction.Q: When is it optimal to utilize a homogenizer with a capacity ranging from 20 to 20,000 T/hr?

A: The flexible capacity makes this equipment ideal for both pilot-scale and large-scale production. It can be employed whenever high-volume, efficient, and consistent homogenization is required, such as during continuous manufacturing runs or batch processing.Q: Where can this homogenizer be installed, and what is involved in its installation?

A: Designed as a free-standing unit, it can be installed in most industrial production facilities. Its straightforward installation requires only a level surface and appropriate utilities, making setup efficient and adaptable to various layouts.Q: What is the process of homogenization using this machine, and what are its key benefits?

A: The machine forces product mixtures through a high-pressure system, breaking down particles and dispersing them uniformly. Key benefits include improved texture, stability, and shelf life of the final product, along with enhanced process control due to automation.Q: How does computerized control contribute to operational efficiency?

A: Computerized controls enable seamless integration with other production systems, facilitate data tracking, and allow operators to adjust settings easily, resulting in minimal downtime, higher productivity, and reduced operational risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Homogenizer Category

LAB High Pressure Homogenizer

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : Approx. 45 kg

Phase : Single Phase

QC System : ISO 9001:2015 Certified

Surface Treatment : Other, Polished Stainless Steel

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry