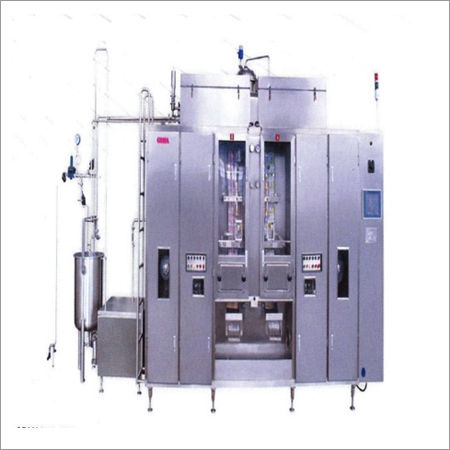

Plate Heat Exchanger-Chiller

Plate Heat Exchanger-Chiller Specification

- Type

- Plate Heat Exchanger-Chiller

- Material

- Stainless Steel

- Capacity

- 5 Ton/Hr

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 380 V

- Frequency (MHz)

- 50 Hz

- Preheating Plate Size

- 300 mm x 800 mm

- Size

- Customized as per requirement

- Width

- 400 mm

- Weight

- 180 kg

- Dimension (L*W*H)

- 1200 x 500 x 1400 mm

- Application

- Chilling, Dairy, Beverage, HVAC, Food Processing

- Plate Material Grade

- SS 304/316

- Heat Transfer Surface

- Corrugated Plates

- Installation

- Floor Mounted

- Flow Arrangement

- Counterflow

- Inlet/Outlet Connection Size

- DN32

- Medium

- Water/Glycol/Chilled fluids

- Operating Temperature Range

- Up to 150°C

- Maximum Working Pressure

- 16 Bar

- Frame Material

- Carbon Steel Painted

- Number of Plates

- 30 Plates

- Cleaning Method

- CIP (Clean-In-Place), Manual possible

- Gasket Material

- NBR/EPDM

Plate Heat Exchanger-Chiller Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-4 Week

About Plate Heat Exchanger-Chiller

Advanced Corrugated Plate Design for Maximum Heat Transfer

The chiller utilizes highly durable corrugated plates made from SS 304/316, enhancing turbulence and efficient heat exchange. The counterflow arrangement allows for superior temperature differentials, making it perfect for demanding chilling and cooling processes in dairy, beverage, and food industries.

Robust Construction and Reliable Performance

With a carbon steel painted frame and high-quality gaskets (NBR/EPDM), this plate heat exchanger is crafted for long-term, reliable operation. It withstands working pressures up to 16 bar and temperatures reaching 150C, ensuring unmatched stability and safety across multiple industrial applications.

Flexible Installation and Easy Maintenance

Designed for floor-mounted setups, our heat exchanger-chiller fits seamlessly in varied production environments. Cleaning is simple with Clean-In-Place (CIP) options or manual servicing, reducing downtime and facilitating hassle-free maintenance routines.

FAQs of Plate Heat Exchanger-Chiller:

Q: How does the counterflow arrangement benefit the heat transfer efficiency in this Plate Heat Exchanger-Chiller?

A: The counterflow configuration allows fluids to flow in opposite directions, maximizing the temperature differential across corrugated plates. This significantly increases the overall heat transfer efficiency, ensuring rapid and precise chilling or cooling in industrial applications.Q: What cleaning methods are recommended for maintaining optimal performance of the unit?

A: The unit supports Clean-In-Place (CIP) as well as manual cleaning methods. CIP is particularly effective for quick, thorough cleaning without disassembly, ideal for sectors requiring stringent hygiene such as food, dairy, and beverage processing.Q: When is this Plate Heat Exchanger-Chiller best suited for use in industrial environments?

A: It is ideal whenever efficient chilling or temperature regulation is required. Industries including HVAC, dairy, beverage, and food processing benefit from its robust design, high working pressure, and reliable automatic operation.Q: Where can this chiller be installed within a facility?

A: The chiller is designed for floor mounted installation and can be positioned in production halls, cooling rooms, or near process lines in factories and plants. Its compact dimensions and customizable size accommodate diverse facility layouts.Q: What are the main advantages of using SS 304/316 plates in this heat exchanger?

A: Using stainless steel grades SS 304/316 ensures high corrosion resistance, durability, and superior thermal conductivity. This material selection supports safe operation with various fluids, even under high temperature and pressure conditions.Q: Can the Plate Heat Exchanger-Chiller handle different mediums like water, glycol, and chilled fluids?

A: Yes, it is engineered to work efficiently with water, glycol, and other chilled fluids, making it versatile for applications requiring precise cooling or temperature control in multiple industries.Q: What are the energy benefits of this automatic grade chiller?

A: The automatic operation optimizes process control and minimizes manual intervention, which can lead to improved energy efficiency and consistent cooling performance in continuous industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Main Processing Equipments Category

Cheese Paneer Vat Press Hoops

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Stainless Steel (SS304/316)

Type : Cheese Paneer Vat Press Hoops

Size : Standard/Custom Sizes Available

10 KLPH Skid Processing Module

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Computerized : Yes

Material : Stainless Steel

Type : Skid Processing Module

Size : Compact Modular Skid

Sanitary Pumps

Minimum Order Quantity : 1 , , Piece

Computerized : No

Material : Stainless Steel

Type : Sanitary Pump

Size : Standard

Yogurt-Cream Pasteurized

Price Range 125000.00 - 1250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Dairy Milk, Cultures

Type : YogurtCream Pasteurized

Size : Standard

|

GOMA ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry